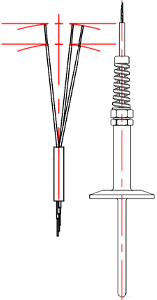

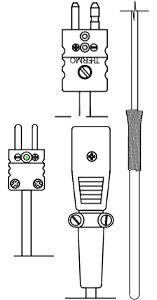

CEPC RTD’s & Thermocouples with Teflon Lead Wire

One of the more commonly used types in the sanitary industry this probe can be supplied in any immersion length and a number of different mating connections. The element conductors terminate inside an epoxy sealed transition housing to TEFLON insulated and jacketed stranded lead wires. The nylon cord grip provides additional strain relief.

| Process Connection: | CIP caps or bevel seats |

|---|---|

| Calibration: | 100 OHM platinum RTD or any Base Metal Thermocouple |

| Probe Diameter: | .25″ |

| Lead Wire: | Teflon |

| Instrument Connection: | Quick-coupling connector, XLR connector or bare ends |

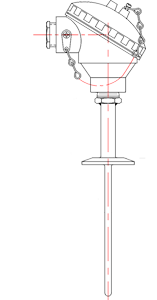

CEPC RTD’s & Thermocouples with Connection Head

Termination to an FDA approved polypropylene, NEMA-4 aluminum or NEMA-4X stainless steel connection head this construction provides for additional protection in a more industrial environment. Heads are equipped with a screw cover cap with captive stainless steel chain to prevent loss. Brass terminal posts on a ceramic base provides simple wiring to the control panel via the conduit opening.

| Process Connection: | CIP caps or bevel seats |

|---|---|

| Calibration: | 100 OHM platinum RTD or any Base Metal Thermocouple |

| Probe Diameter: | .25″ |

| Connection Head: | White Polypropylene, Aluminum, or Stainless Steel |

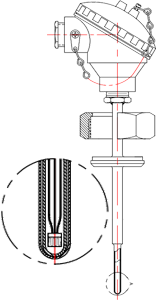

CEPC RTD’s & Thermocouples with Head, Thermowell

Complete with connection head, sensor and reduce tip type well for faster response time this type of construction provides additional protection in a more industrial location. The sensor is terminated with a DIN style spring loaded integral terminal block allowing convenient removal for inspection or replacement.

| Process Connection: | CIP caps or bevel seats |

|---|---|

| Calibration: | 100 OHM platinum RTD or any Base Metal Thermocouple |

| Probe Diameter: | .25″ |

| Well: | Reduce Tip |

| Connection Head: | White Polypropylene, Aluminum, or Stainless Steel |

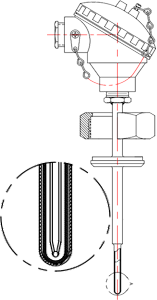

CEPC RTD’s & Thermocouples with Head, Thermowell

Complete with connection head, sensor and well this type of construction provides additional protection in a more industrial location. The sensor is terminated with DIN style spring loaded integral terminal block for convenient removal for inspection or replacement.

| Process Connection: | CIP caps or bevel seats |

|---|---|

| Calibration: | 100 OHM platinum RTD or any Base Metal Thermocouple |

| Probe Diameter: | .25″ |

| Well: | Straight Shank |

| Connection Head: | White Polypropylene, Aluminum, or Stainless Steel |

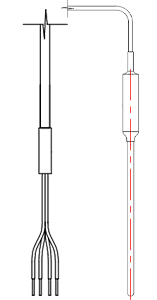

Building Management System Replacement

Ideal for monitoring cooling and heating systems in buildings. These easy to install probes can be fabricated to any desired immersion and lead length. Optional bell spring provides strain relief when pulling wires through conduit. Leads are terminated to skin ends or a choice of connectors.

| Process Connection: | Direct Immersion |

|---|---|

| Calibration: | 100 OHM platinum RTD or any Base Metal Thermocouple |

| Probe Diameter: | .125″, .187″, or .25″ |

| Lead Wire: | Teflon |

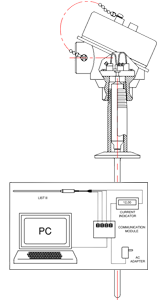

L.I.S.T II Linear Integrated Sensor Transmitter

The L.I.S.T II transmitter combines the stability and accuracy of an RTD with the benefits of an integral 4 to 20 mA signal condition device. This device can be installed directly into the process or existing thermowell and secured with standard compression fittings. Completely self contained the lead wire can be ordered in any length to provide output signal and voltage power source from the control panel.

| Process Connection: | Direct Immersion |

|---|---|

| Calibration: | 100 OHM platinum RTD, with 4 To 20mA Output |

| Probe Diameter: | .187″ or .25″ |

| Lead Wire: | Teflon |

L.I.S.T II with CIP & Head Field Programmable

The L.I.S.T II transmitter combines the stability and accuracy of an RTD with the benefits of an integral 4 to 20 mA signal condition device. Termination to an FDA approved polypropylene, NEMA-4 aluminum or NEMA-4X stainless steel connection head this construction provides for additional protection in a more industrial environment The transmitter is safely contained in the nipple housing. Heads are equipped with a screw cover cap with captive stainless steel chain to prevent loss. Terminal block provides wiring for output signal and voltage power source.

| Process Connection: | CIP Tri-Clamp Cap |

|---|---|

| Calibration: | 100 OHM platinum RTD, with 4 To 20mA Output |

| Probe Diameter: | .187″ or .25″ |

| Connection Head: | White Polypropylene, Aluminum, or Stainless Steel |

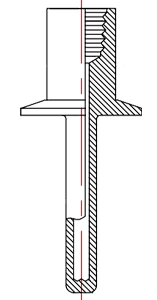

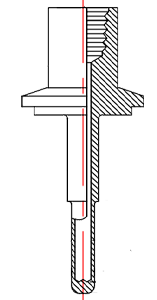

CIP Thermowells 16AMP Clamp Connection

Bored through solid bar stock well connects to matching line size with clamp for a clean-in-place seal. The 1/2″NPT threaded opening allows for insertion of element with mating compression fitting or nipple extension. The step down tip allows for faster sensor response time.

| Process Connection: | 16AMP Clamp |

|---|---|

| Size: | 1/2″ to 3″ |

| Material: | 316/316 Low Carbon Stainless Steel |

| Profile: | Straight or Step Down |

CIP 16A1-141 & 16AQ-14 Clamp Connection

Bored through solid bar stock well connects to matching line size with clamp for a clean-in-place seal. The 1/2″NPT threaded opening allows for insertion of element with mating compression fitting or nipple extension. The step down tip allows for faster sensor response time.

| Process Connection: | 16A1-141 & 16AQ-14 Clamp |

|---|---|

| Size: | 1/2″ to 3″ |

| Material: | 316/316 Low Carbon Stainless Steel |

| Profile: | Straight or Step Down |